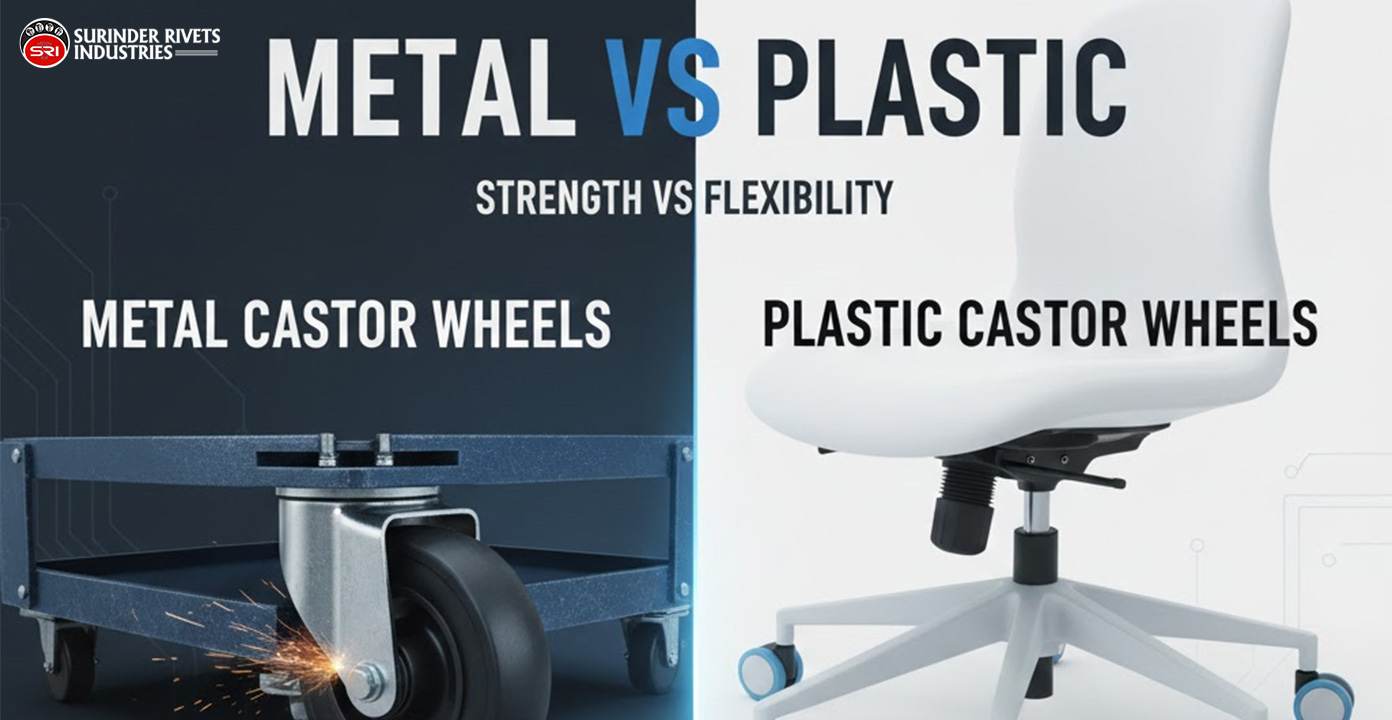

Castor wheels play a crucial role in mobility, load handling, and operational efficiency across industries such as manufacturing, warehousing, healthcare, furniture, and logistics. Choosing the right castor wheel material—metal or plastic—can significantly impact performance, safety, durability, and maintenance costs.

In this guide, we compare metal castor wheels vs plastic castor wheels in detail to help you make an informed decision based on your application needs.

Castor wheels are mounted components that enable smooth movement of equipment, trolleys, carts, and machinery. They are available in different materials, sizes, load capacities, and mounting types. The wheel material determines how well the castor performs under weight, environmental conditions, and surface types.

Metal castor wheels are typically made from steel, cast iron, or stainless steel. They are designed for heavy-duty and industrial applications where strength and durability are critical.

Plastic castor wheels are generally manufactured using nylon, polypropylene, or reinforced polymers. They are lightweight and designed for light to medium-duty applications.

| Feature / Parameter | Metal Castor Wheels | Plastic Castor Wheels |

|---|---|---|

| Material Composition | Steel, cast iron, stainless steel | Nylon, polypropylene, reinforced plastic |

| Load Capacity | Very high, suitable for heavy-duty applications | Low to medium, suitable for light loads |

| Durability | Extremely durable and impact-resistant | Moderate durability under normal use |

| Weight of Wheel | Heavier | Lightweight |

| Floor Impact | Can damage delicate floors | Floor-friendly and non-marking |

| Noise Level | Can be noisy on hard surfaces | Quiet and smooth operation |

| Temperature Resistance | Performs well in high-temperature environments | Limited heat resistance |

| Corrosion Resistance | Good, especially stainless steel variants | Excellent resistance to moisture |

| Maintenance Requirement | Low but requires occasional inspection | Very low maintenance |

| Cost | Higher initial cost | Economical and budget-friendly |

| Shock Absorption | Minimal | Better shock absorption |

| Typical Applications | Industrial trolleys, heavy machinery, factories | Office furniture, hospital equipment, carts |

| Lifespan | Long service life | Shorter compared to metal wheels |

| Best Usage Environment | Harsh, industrial, outdoor conditions | Indoor, commercial, medical environments |

Winner: Metal Castor Wheels

Winner: Metal Castor Wheels

Winner: Plastic Castor Wheels

Winner: Plastic Castor Wheels

Winner: Metal Castor Wheels for harsh conditions

Winner: Depends on usage requirements

Regardless of whether you choose metal or plastic castor wheels, fastening quality plays a critical role in safety and performance. Poor-quality bolts, rivets, or screws can lead to instability, vibration, and premature failure.

At Surinder Rivets Industries, we understand that mobility systems are only as strong as the fasteners that hold them together.

Our commitment to precision engineering, quality control, and customer satisfaction makes us a trusted partner for industrial fastening needs.

Both metal and plastic castor wheels have their advantages. The right choice depends on load requirements, environment, floor type, and budget. Pairing the correct castor wheel with high-quality fasteners ensures optimal performance, safety, and longevity.

For reliable fastening components that support robust mobility solutions, Surinder Rivets Industries stands ready to meet your requirements with precision and trust.